EFCO guarantees their clients

the best competitive quality,

cost and the on time delivery

Sucsess Partener

Services

Always care to stand with our clients by the all possible efforts to make him satisfied about what we make .our integrated acility provide u some service that surely will be in need of it.

Repair service

Efco here to reduce your overall down time and costs with top quality machinery....

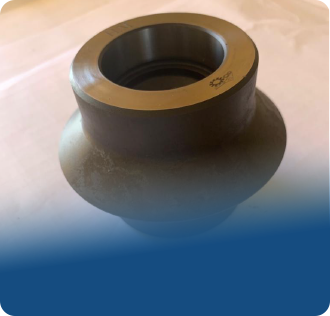

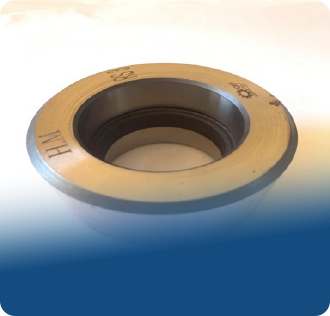

Special Material

As we are integrated facility EFCO imports any material that client needs in very .....

Heat Treatment

As u deal with EFCO, you are getting one of the best steel heat treatment services...

Reverse Engineering

Reverse engineering refers to the process of copying an existing product for the....

on time

The team is very professional and meticulous, we observe all quality control standards and productivity to deliver your work on time with international quality

Around world

We reach the extreme, delivering our professional work to all parts of the world in the fastest time while ensuring the safety of your products from any damage during shipping

Products

Always care to stand with our clients by the all possible efforts to make him satisfied about what we make .our integrated acility provide u some service that surely will be in need of it.

quality control

To specify the various physical and mechanical properties of the finished product, various tests, both destructive and nondestructive, are performed. Metallurgical, hardness, hardenability, tension, ductility, compression, fatigue, impact, wear, corrosion, creep, machinability, radiography, magnetic particle, ultrasonic, and eddy current are some of the major tests that are performed by quality control personnel.

Machinery

We much care in development and investment in our facilities and machinery so we keen on bringing highly branded and accurate machines to supply our clients the needed quality

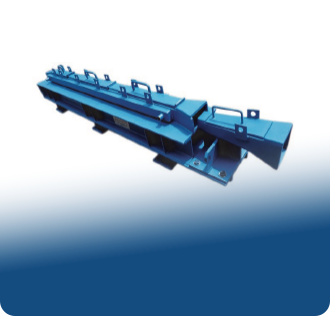

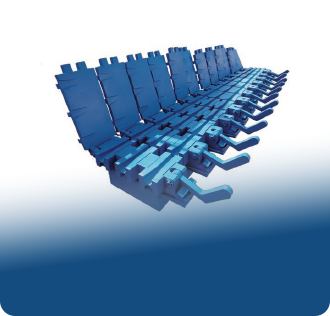

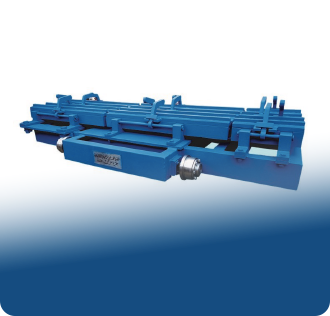

Fabrication

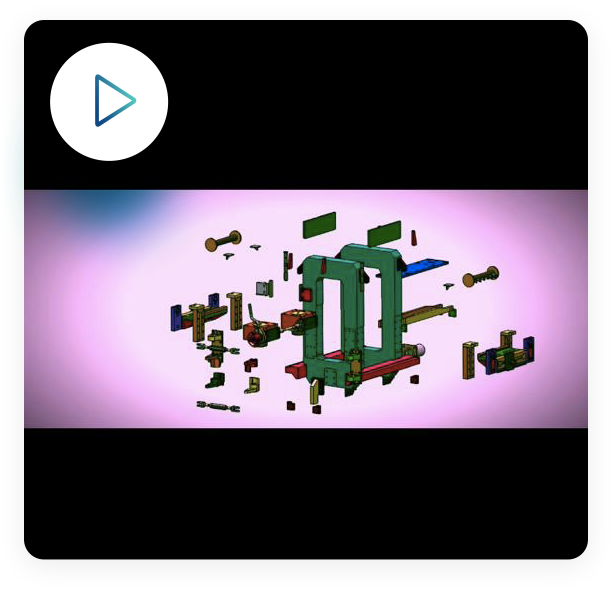

There are many types of fabrication techniques EFCO use where the most common ones are cutting and machining, punching and drilling, straightening, bending and rolling, fitting and reaming, fastening, finishing etc. A few types of fabrication techniques used in EFCO are listed below in detail for the rolling stand project

Step .3

Welding:

To join two pieces of metal, welding is done. Various kinds of welding is performed on range of metals used for diverse applications

Step .4

Closure:

Finally, the painting methods come to complete the product and deliver it to the customer

Step .5

Delivery:

The product is prepared for delivery to the customer after ensuring the safety of all parts and tasks related to the product

In numburs

We supply the highest precision parts to a variety of the biggest steel, cement, fertilizers, telecommunications and food manufacturers in the Middle East.

Our cleints